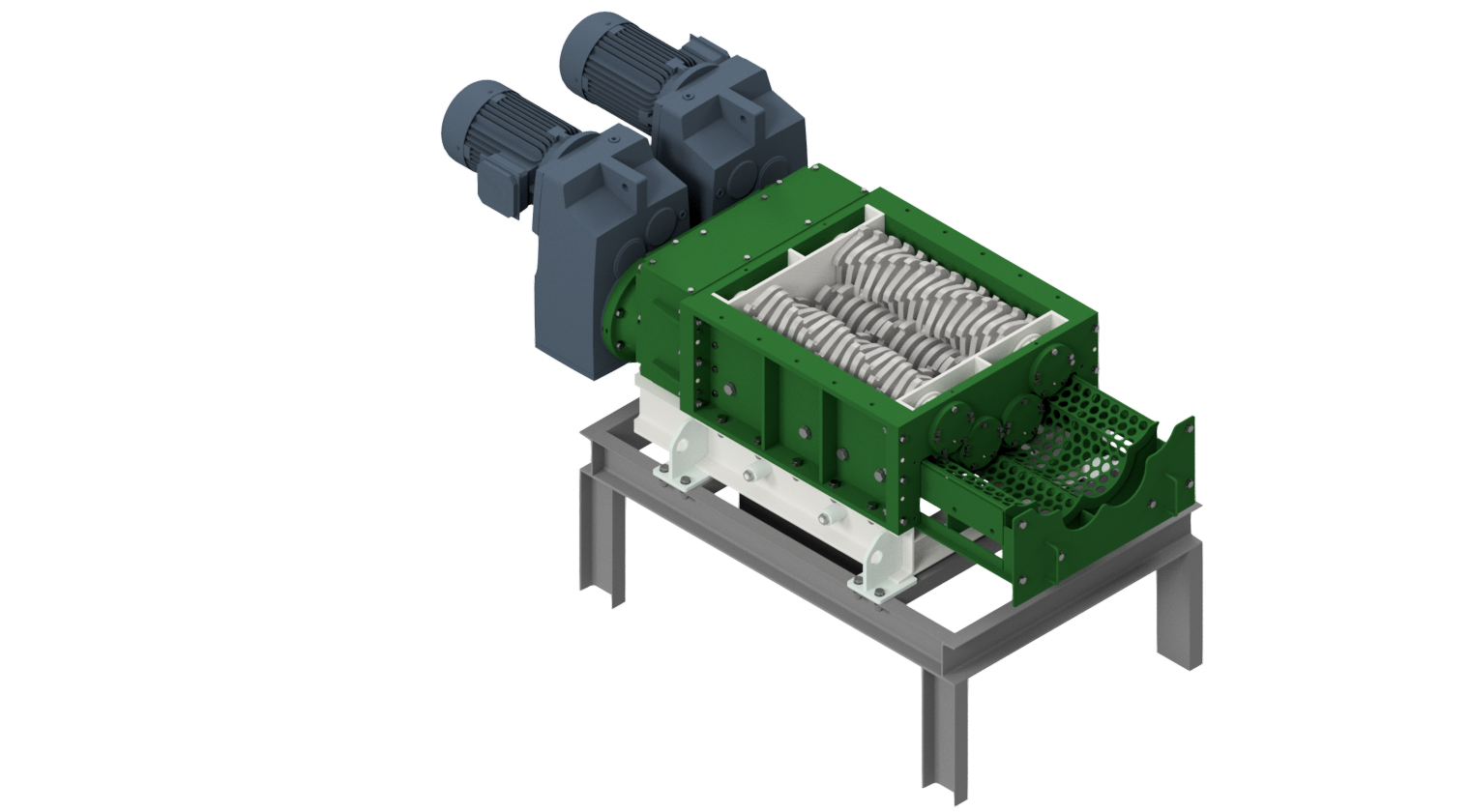

Peat shredding is provided by a four-shaft rotary shredder with knives driven by two electric gearboxes.

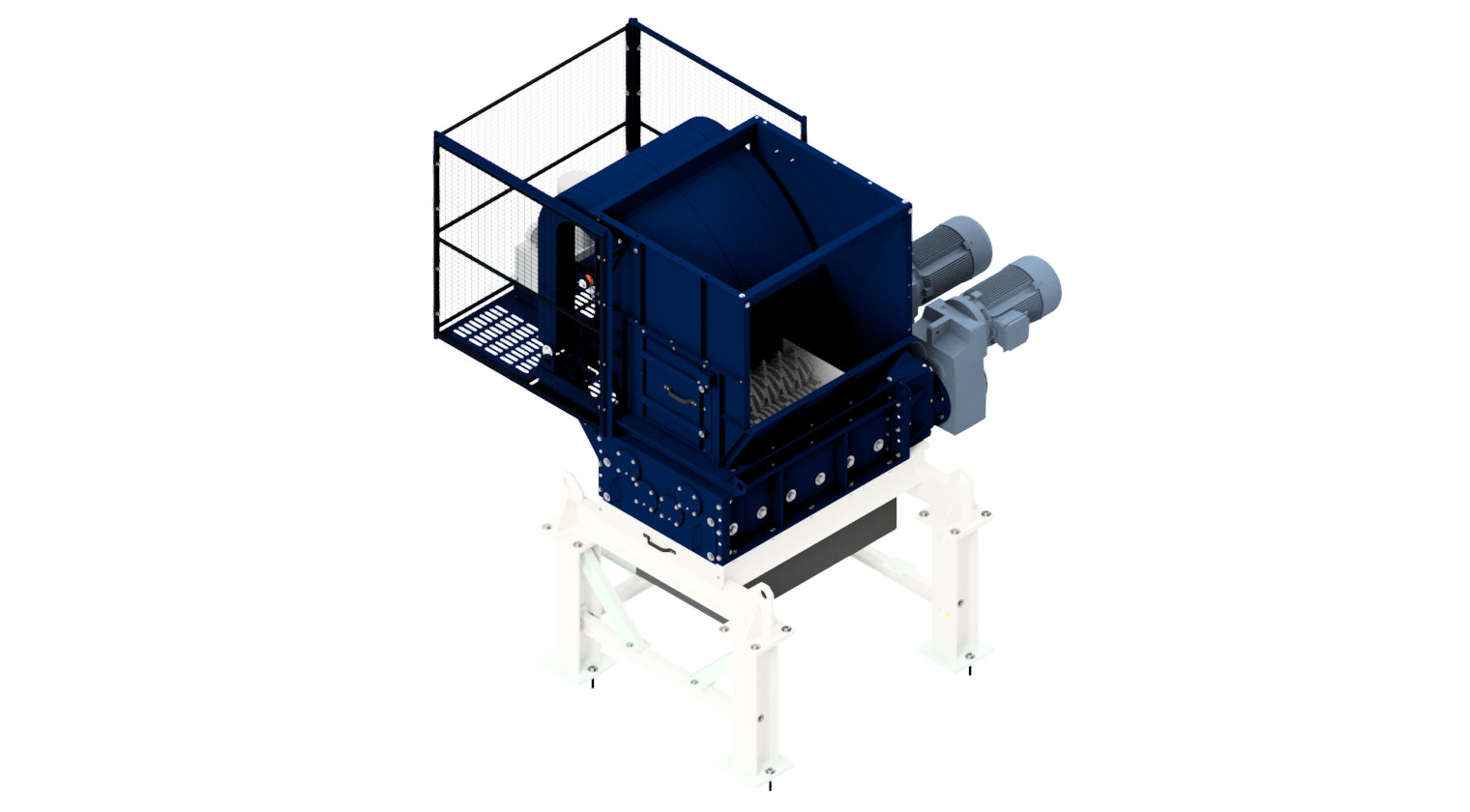

A four-shaft shredder designed for waste processing lines, sorting facilities, heating plants, incinerators (PET bottles, plastics, paper, cables, cardboard, wood), lines for processing composts, peat, etc. These shredders shred waste or material into the required smaller output fraction, whose size depends on the mesh size. The screen is located under the crusher segments. It is used where the input waste is large in volume or in size and must be shredded into small pieces in one step. The shredder is fitted with four shafts rotating opposite each other and shredding the waste or material between each other; at the same time the output is calibrated by the screen through which it falls onto a conveyor. The resulting crushed material can be used as alternative fuel, for further processing or simply for decreasing waste volume, for cheaper and more environment-friendly transport (so as not to transport air).

Shredders can be stationary or mobile with optional power generator for removal of dump sites in multiple areas. Shredders are equipped with automatic control system, which does not require too much attention from the operator. Control system actively monitors and controls overloads, set reverse counts and operational hours.