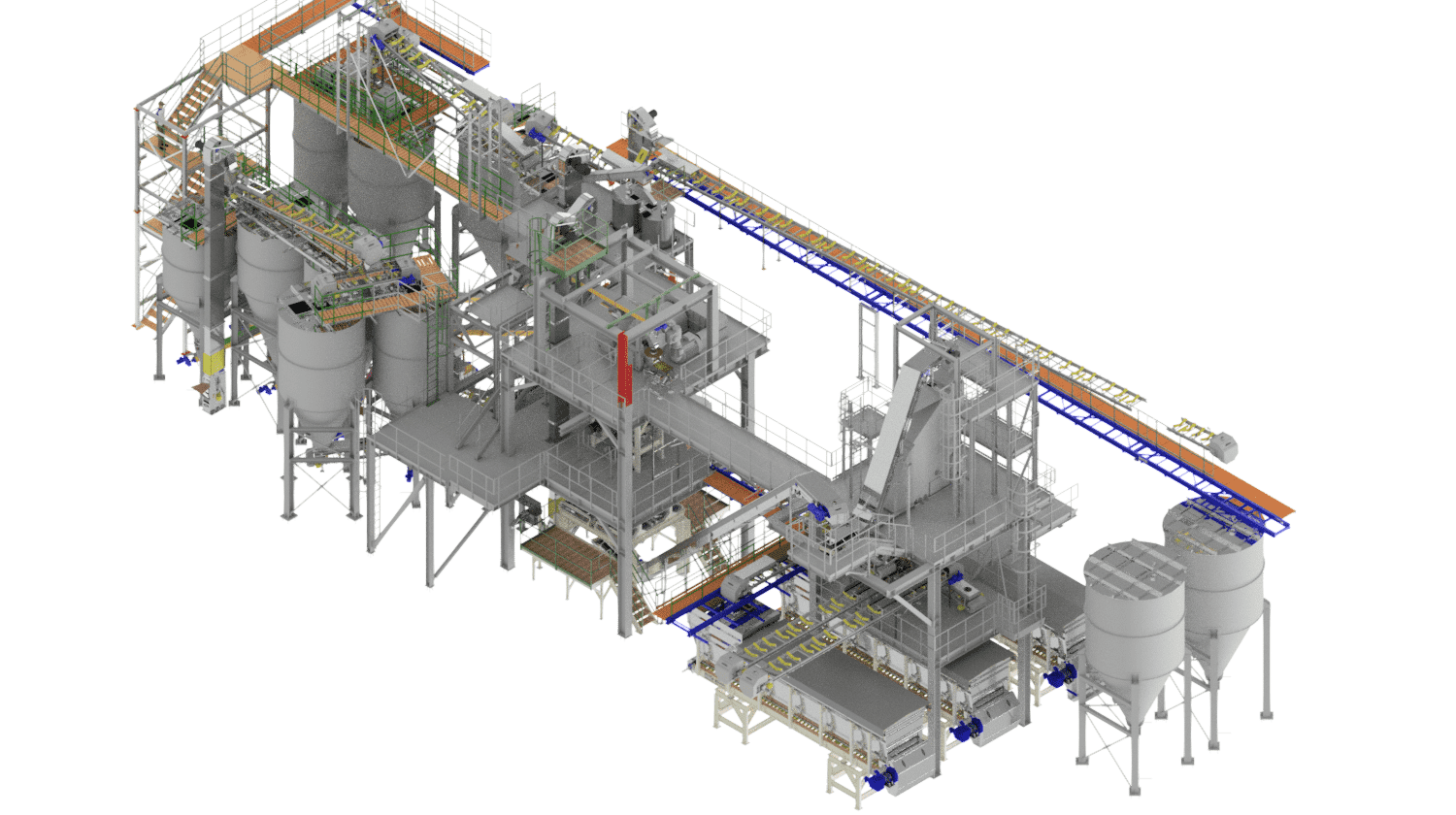

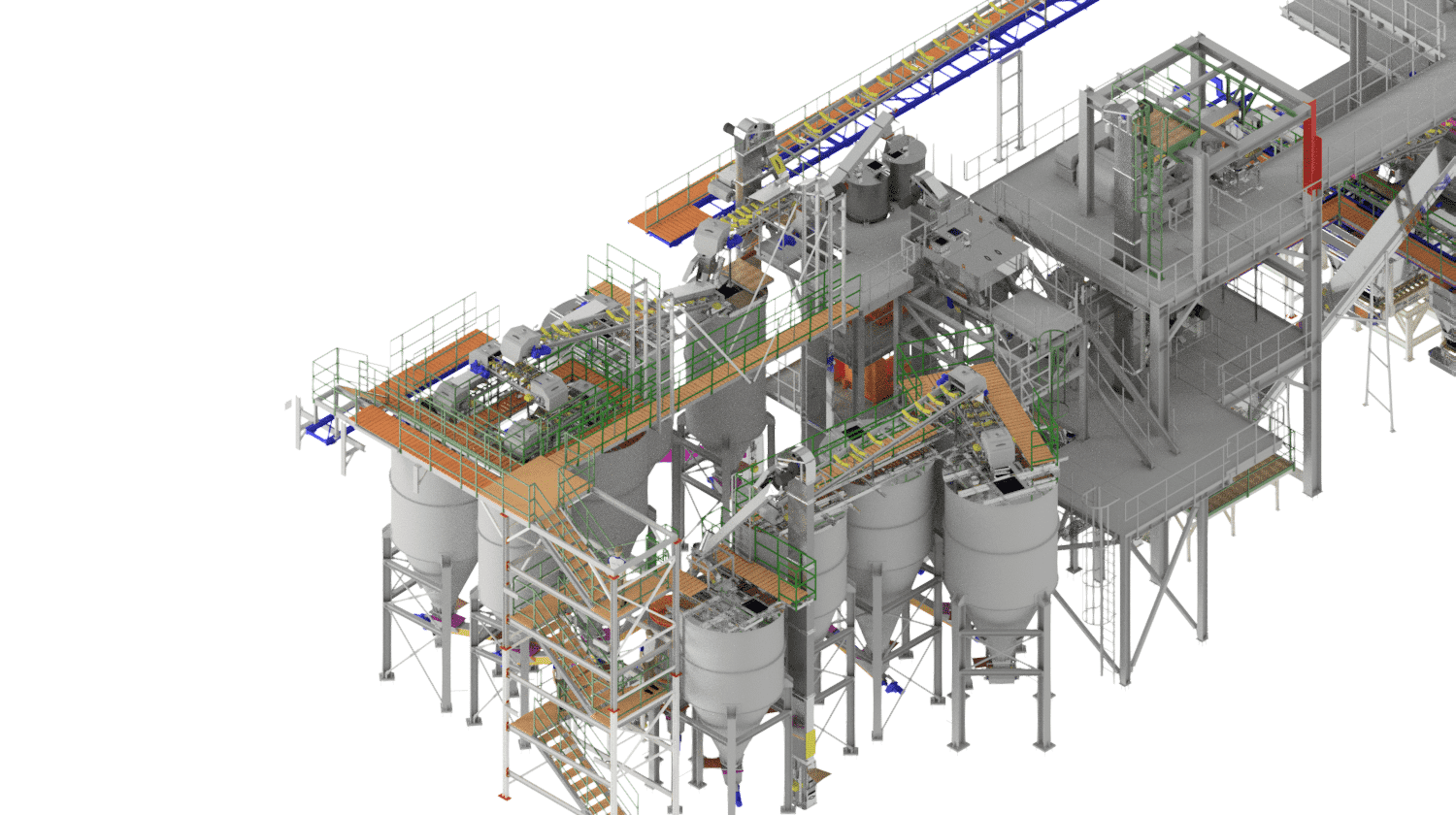

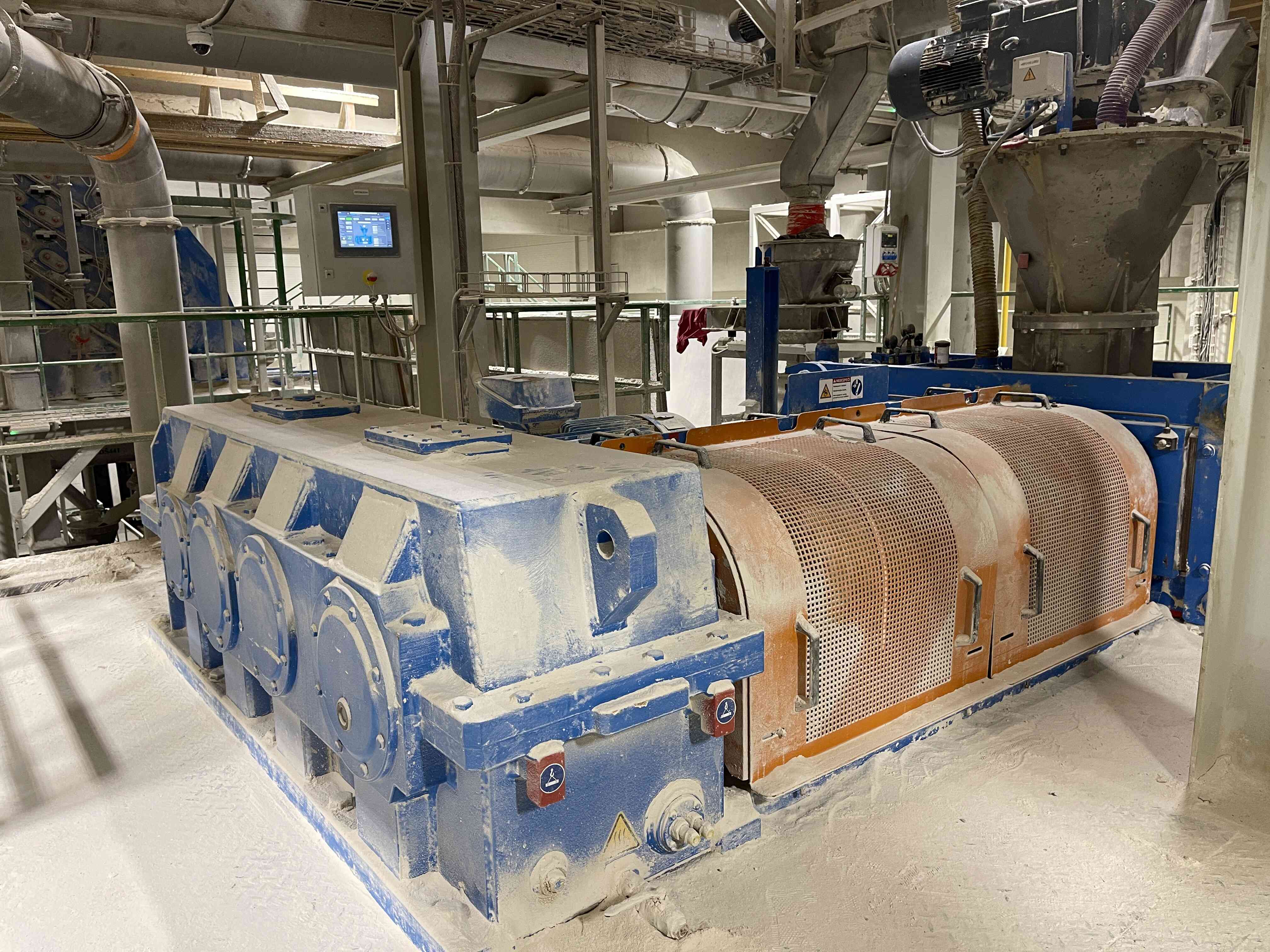

Compaction is the process of producing a complete fertilizer granule from single component ingredients in a dry way, each granule containing a set ratio of input raw materials, i.e. nutrients, according to the selected recipe. It is a highly efficient technology, whereby a mixture of input materials under high pressure produces a continuously compacted slab, which is then crushed into individual granules. It is a closed, waste-free process for the complete processing of input raw materials into a product.

The line allows for a high variability of recipes, fertilizer composition and a rapid change of the production range.

The performance of the compacting line depends on the customer's requirement, which is adapted to the size of the individual equipment of the line.

The compacting process consists of 8 sub-processes:

- Feedstock hoppers with weighing outputs to ensure the correct mix ratio.

- Grinding of feedstock

- Mixing of the mixture

- Compaction of the mixture with subsequent granulation

- Sorting of the compact

- Air handling

- Product maturation

- Surface treatment of granules

Our company is able to build a turnkey compacting line including hardware, control software, precise monitoring of individual parameters and process stages.

When delivering a turnkey line, we provide full technological support and preparation of all necessary documentation. The delivery also includes training of management and line operators in the design and commissioning phase, operation and maintenance of the production equipment.