The filling equipment is designed for filling 20 and 40-feet shipping containers with bulk materials. These include mainly granulated mineral fertilizers and crop commodities, such as flax seed, chickpeas, peas, rapeseed, rice, safflower, wheat, millet, sunflower seed, barley, corn, oats, bran, and buckwheat hulls (hereinafter as material).

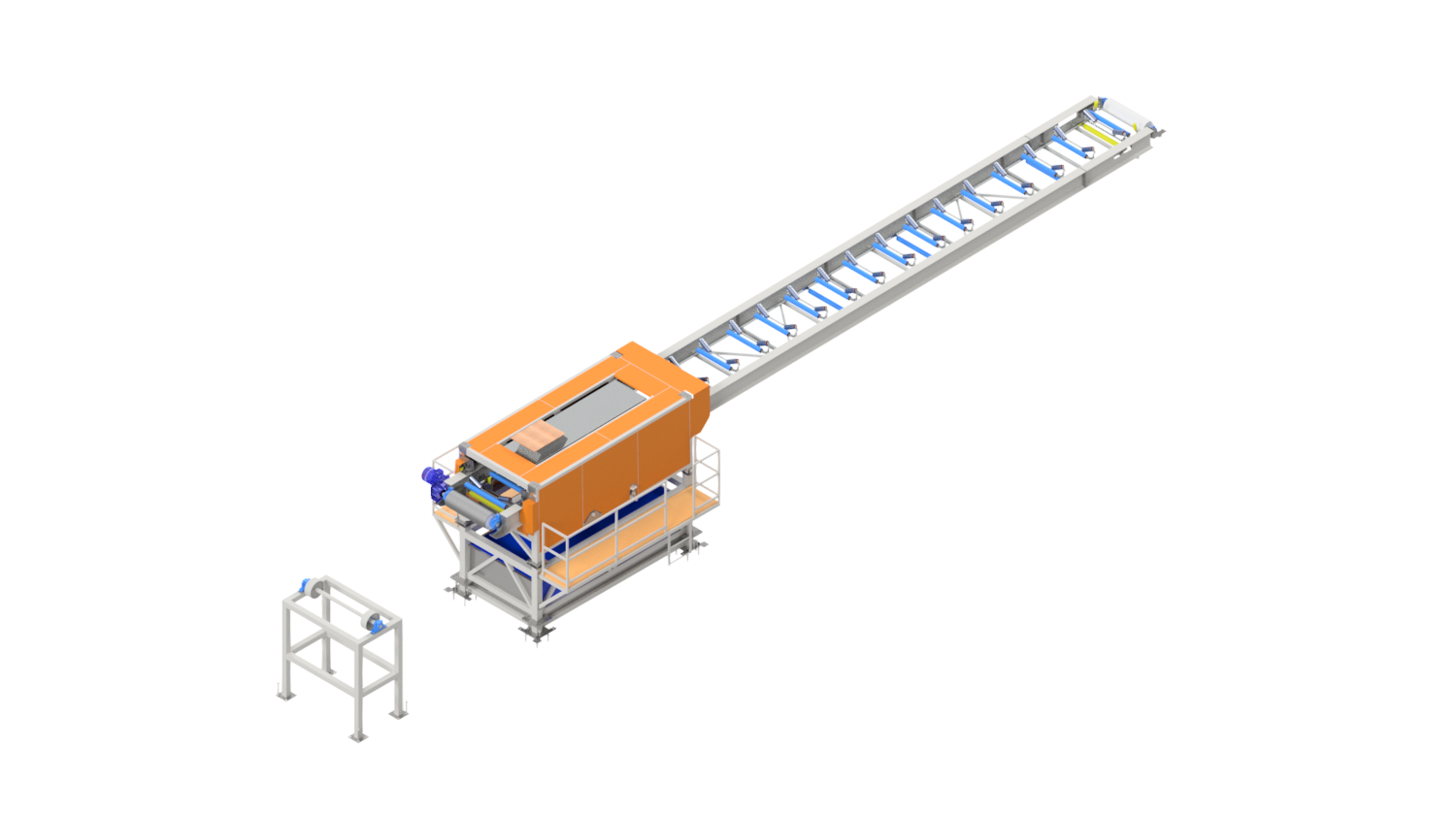

The filling equipment consists of a robust frame and retractable belt conveyor with up to 10.5 m retraction length. The retractable conveyor is loaded by a continuous hopper on a frame.

The belt conveyor is made from a combination of structural and stainless steel and is equipped with triple-roller benches and fitted with rubber-textile conveyor belt with stepless speed control. The motion of the conveyor inside and out of the container is also continuously controllable upon the instantaneous weight of the container. For a better utilization of the container’s volume the filling equipment can be complemented by a rotating disc distributor to ensure an even distribution of the material; this is convenient mainly for materials with lower bulk density. With this adaptor the container utilization increases up to 96 %. The drive and travel of the belt are provided by electrical gearboxes. The equipment comes with electrical installation and automation ensuring accurate control of the filling process by the size of the container and type of material.

The filling equipment could be fed with material from unloading line for railroad cars or trucks.

Filling procedure

An empty container is placed on weighted bench with an open front facing the filling equipment. First of all, the type of the material to be filled and the size of the container are selected on the control panel display. Then the conveyor is shifted to the far end of the container and an automatic filling process begins. From this point onwards, everything is controlled automatically, that means the rotating disc distributor is engaged and the feeding of the material begins. The container is filled from the rear end. The filling equipment continuously moves in an outward direction until the container is fully filled.