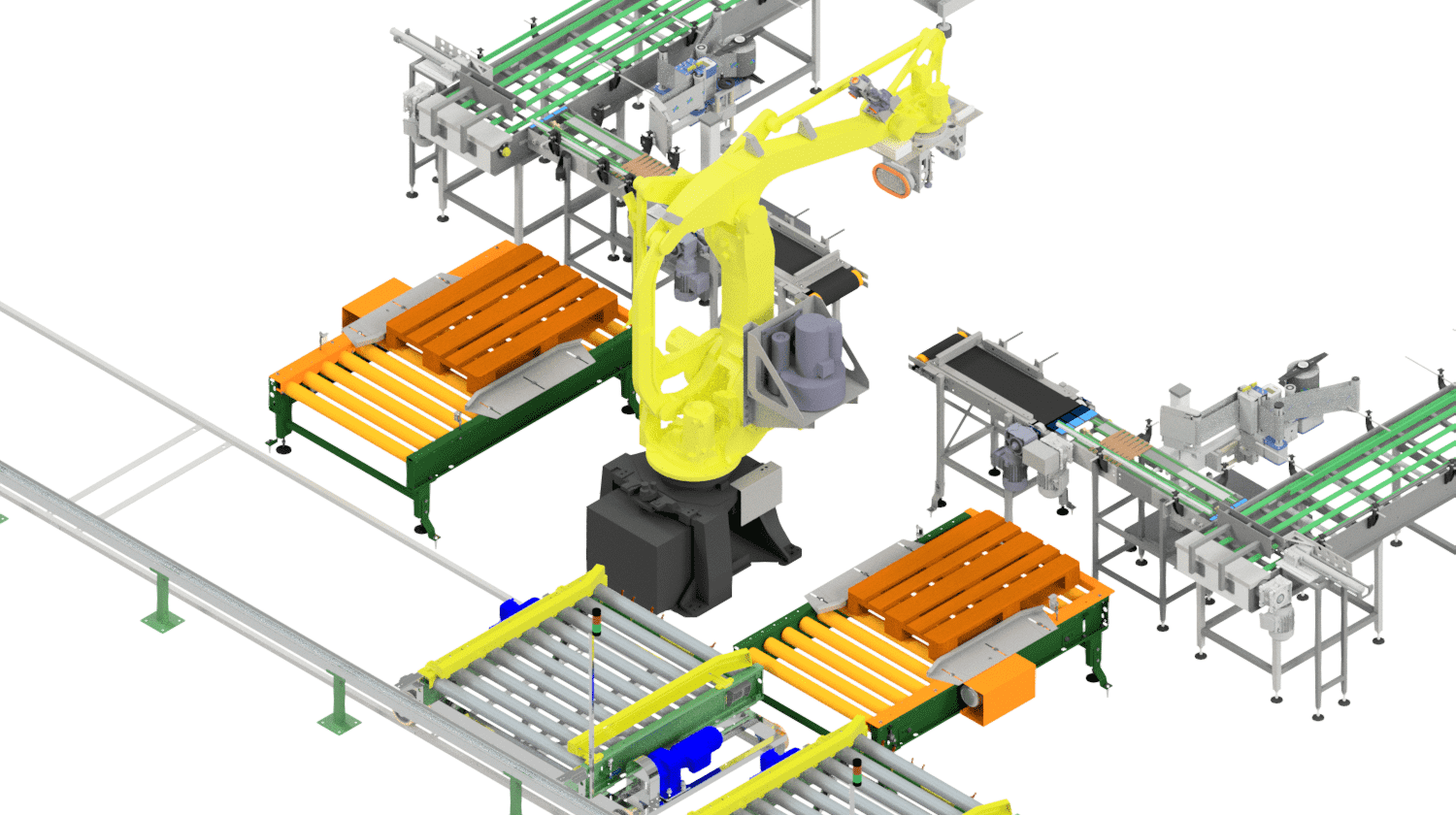

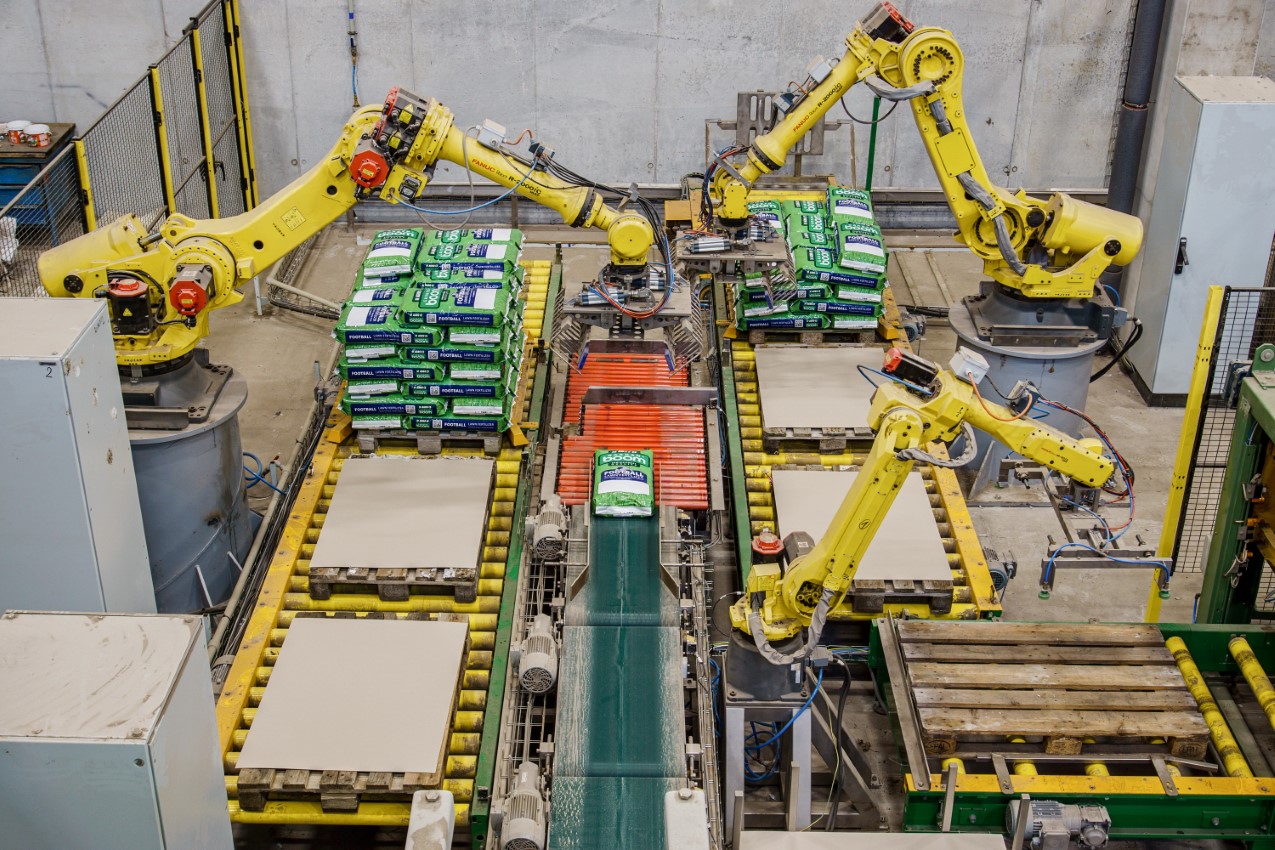

The robotic workstation uses a robotic arm (or arms) with programs for individual straightening pattern to align the goods on the pallet. The robot picks a bag with goods from the picking point, in front of which buffer points are designed according to performance, and places them on the straightening point. Before the first bag is placed, an empty pallet is automatically placed on the straightening station. After the straightening process, the straightened pallet leaves for fixing by wrapping with foil (wrapper or stretch hood). Depending on the performance of the robotic workplace, we design the entire system, the number of robots and the control of the entire palletizing process, including remote management of the quantity and type of palletized goods. We use FANUC robotic arms in our technology.

Robotic workstation RP

Technical data

| Basic technical data | |

|---|---|

| Performance | up to 10 bags per minute |

| Power input | up to 20 kW |