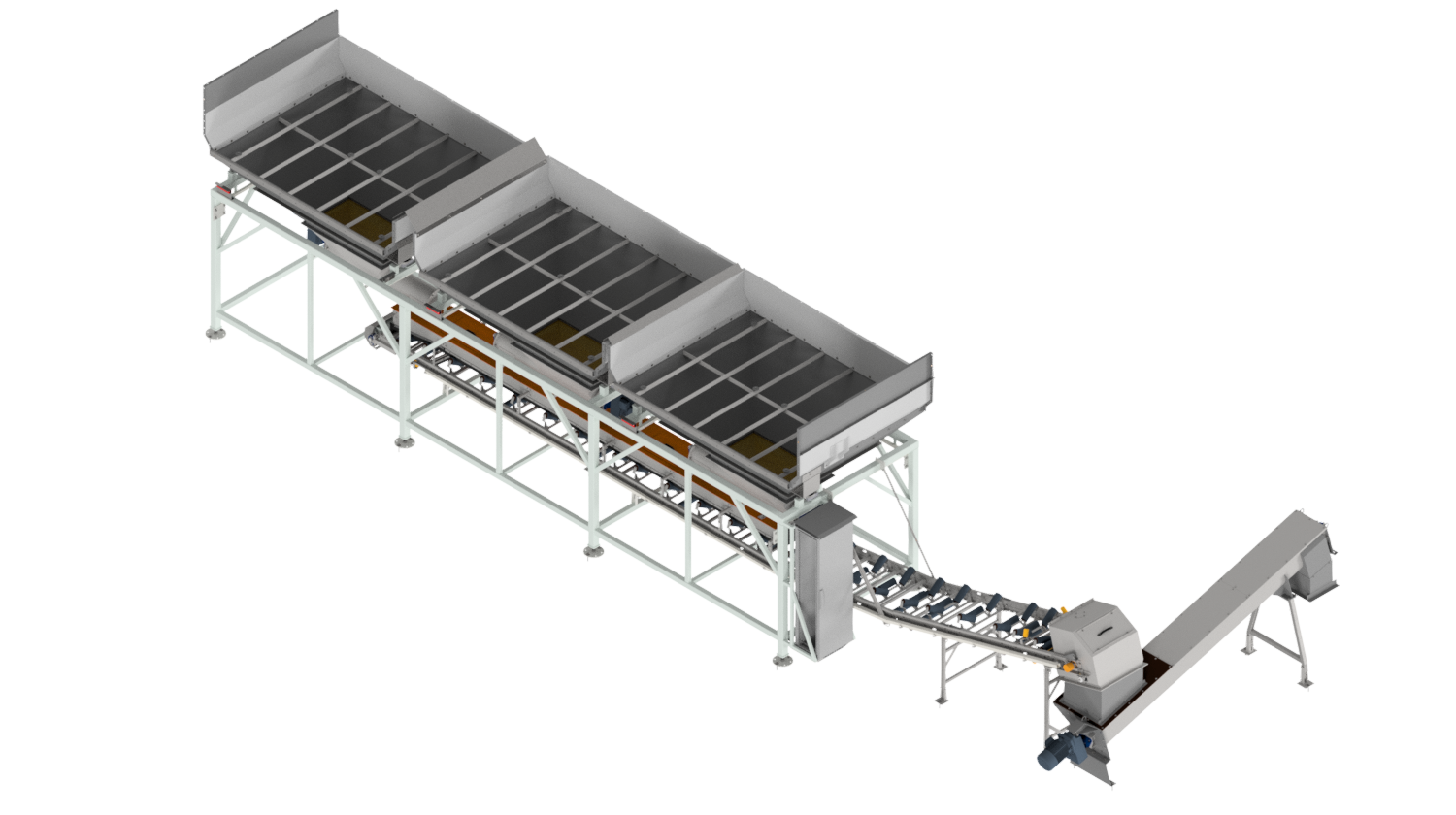

The machine is designed for production of compound granulated mineral fertilizers with the possibility of adding modifiers to the fertilizers (liquid or bulk powder micro-elements, inhibitors, nitrification, anti-caking agents, etc.). Depending on the number of the filling hoppers, the machine produces compound fertilizers containing 2 to 8 components.

Hoppers with feeder srews are made of stainless steel. The hoppers are installed on load cells attached to a supporting frame. The frame is coated with chemical-resistant paints. The hopper is equipped with protective stainless-steel sieves with 50 x 50 mm mesh. The hoppers are filled with a front loader without the need to pause the process and risk of the loss of batching accuracy.

The filling hopper feeders accurately dose the components onto the collecting conveyor in layers, which ensures the requested blend ratio in vertical ”sandwich” of the blend before mixing. The collecting conveyor delivers the fertilizer layer into the screw mixer where the mixture is blended to ensure an even distribution of the components throughout the entire volume.

The machine is controlled by PLC with with 12-inch touch screen control, which clearly displays settings and current status of the production process.