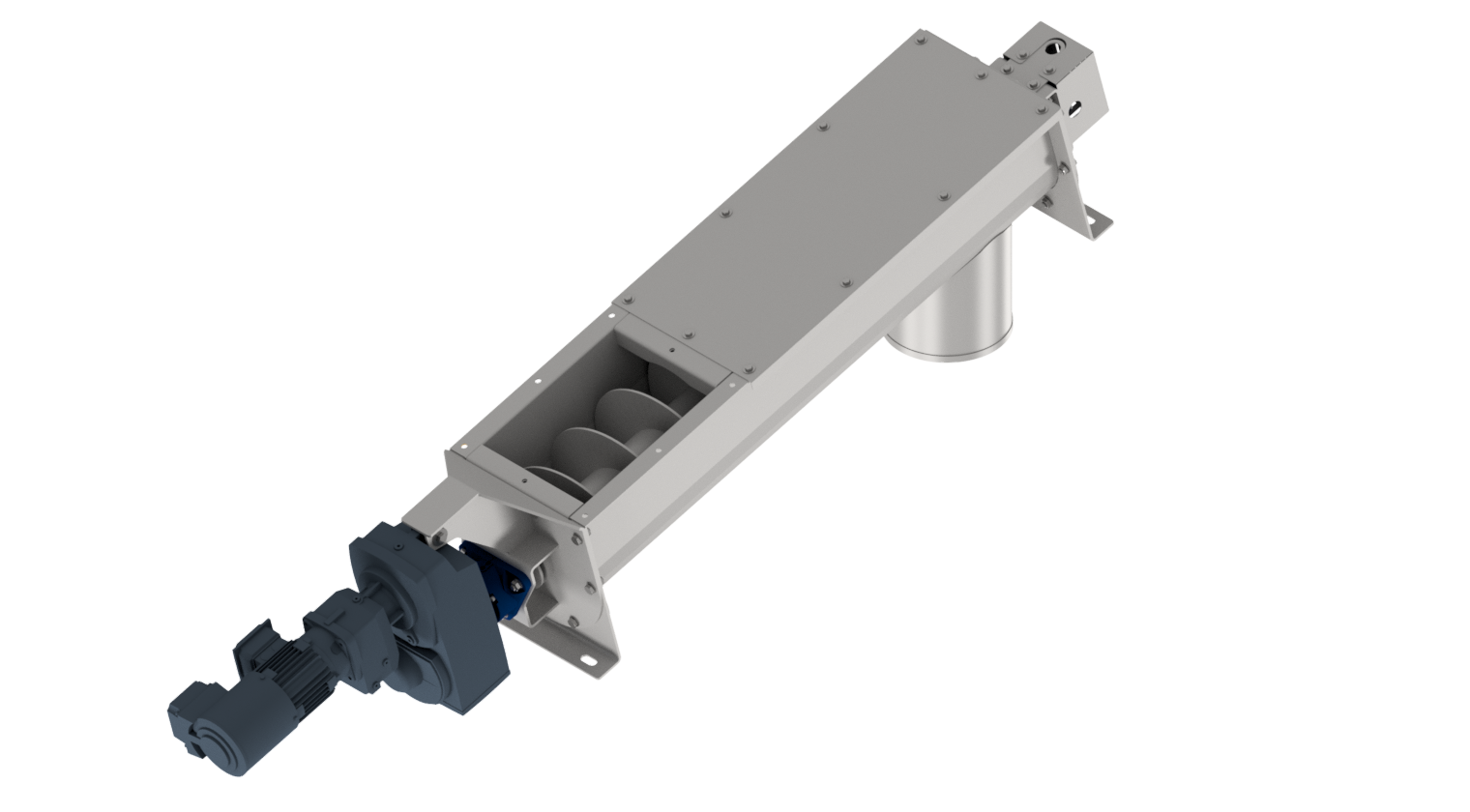

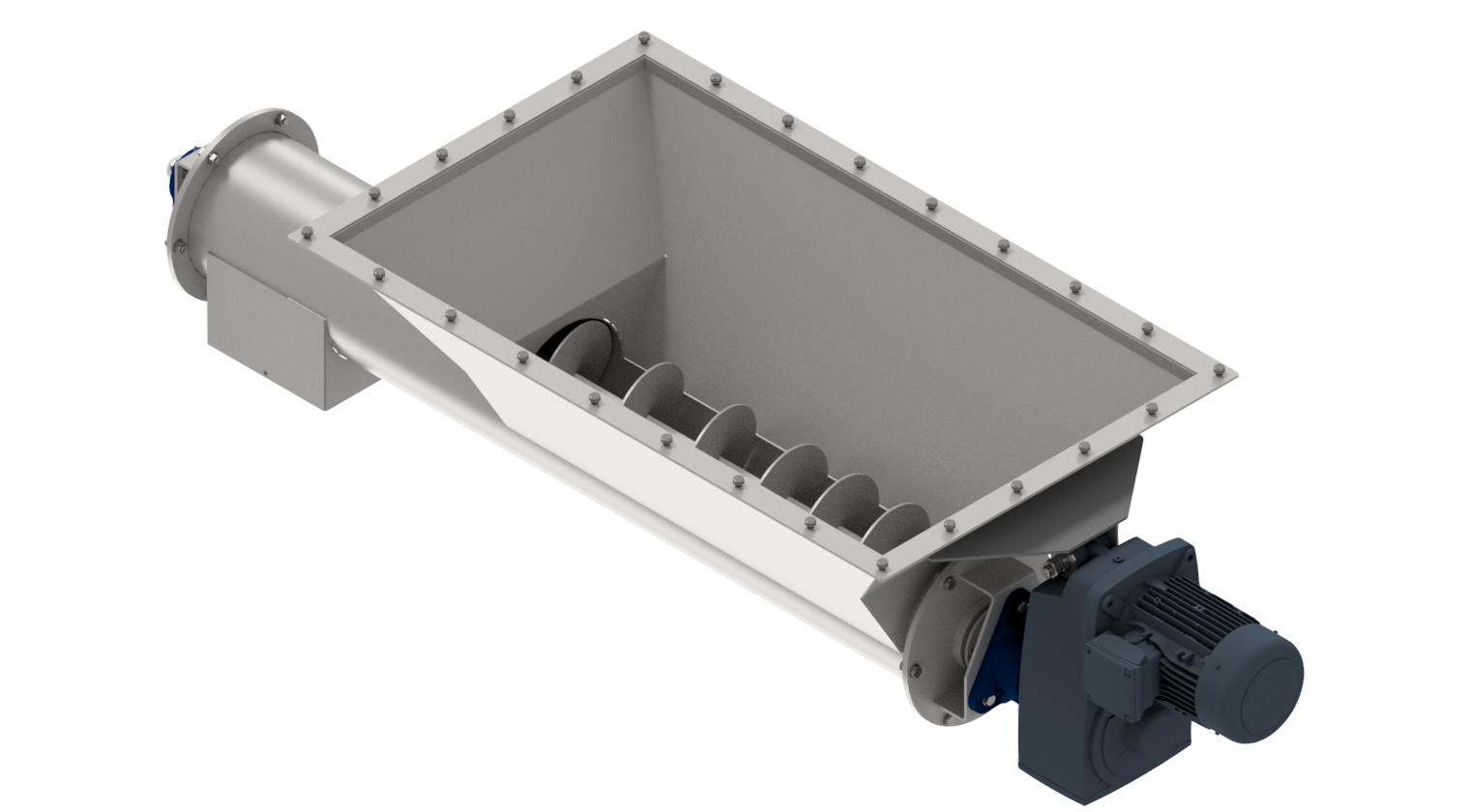

A screw conveyor is a device used to transport bulk materials or liquids in various industrial sectors. It consists of a rotating helical blade (screw) within a cylindrical or trough-shaped tubular housing. This system is efficient for horizontal, inclined, or vertical material transportation.

Use of Screw Conveyor

Screw conveyors are widely used in industrial processes where materials such as the following need to be transported:

- Agricultural products (grain, feed)

- Mineral fertilizers

- Powdered and granulated chemicals

- Construction materials (cement, sand)

Advantages of Screw Conveyor

- Efficient transportation: Screw conveyors allow efficient and smooth material feed, increasing productivity and streamlining work processes.

- Precise dosing: The controlled movement of the screw allows precise regulation of the transported material quantity, which is crucial for applications requiring exact dosing.

- Versatility: Screw conveyors can operate in various directions (horizontally, inclined, vertically), making them highly versatile and suitable for a wide range of applications.

- Compact design: Due to their compact design, screw conveyors can be easily integrated into existing production lines and space-limited areas.

- Closed system: The closed design of the screw conveyor minimizes the risk of material contamination while protecting the work environment from dust and material leakage.

Materials for Manufacturing Screw Conveyors

- Stainless steel

- Steel grade 11

Due to their versatile properties and robust construction, screw conveyors are a key element in many industrial applications that require reliable and efficient material transportation.