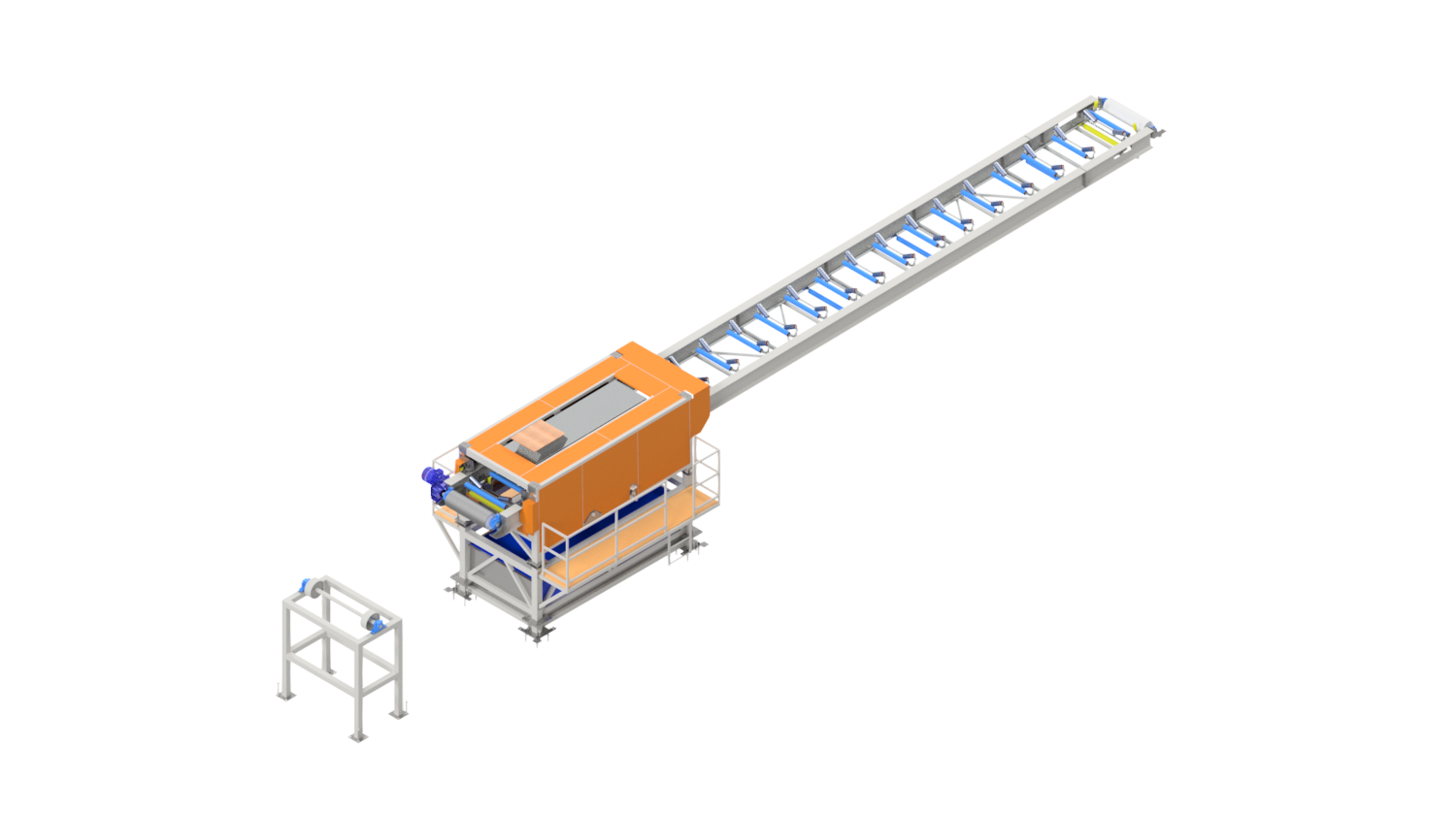

A transmodal terminal at a seaport had requested a line for the unloading of bulk granulated fertilizers from railway wagons and reloading them into maritime shipping containers. AGRO CS had developed a set of 2 special telescopically retracting belt conveyors that automatically alternate in shifting into 40’ or 20’ sea containers, i.e. a regime when one container is being filled while the other one is being prepared for filling.

Using an automatic measurement of the container’s fullness the filling conveyors gradually fill the entire volume from the rear end towards the front gate. The customer had requested up to 96 % filling capacity, therefore the belt conveyor has a specially controlled rotating disc distributor at its end that makes sure the reloaded material reaches all the way up to the ceiling and achieves the required filling capacity without any costly additional structures tilting the containers vertically. As the entire line, consisting of unloading, movement routes, and sliding telescopic filling conveyors, is made of stainless steel, depending on the market demands the customer uses it also for the reloading of foodstuffs, such as legumes and grains.